Foundation Formwork Systems

Technical specifications type FS-U-Form:

| Element length with overlapping: | 0.9 m |

| Element length actual: | 0.85 m |

| Element height: | according to specifications |

| Profiling of lateral wall: | 10 x 26 mm |

| Push-in brackets: | ø 8 mm, as accessory |

| Recommendation for bracket distance: | approx. 1 m |

| System components: | 1 (casing) |

| Weight per sqm: | approx. 4.5 kg |

| Free-standing cement height: | to 0.4 m with distance brackets |

| Available in radius: | no |

| Available with base plate laying: | yes |

| Delivery time per casing: | short-term |

| Assembly times: | approx. 0.1 h/qm |

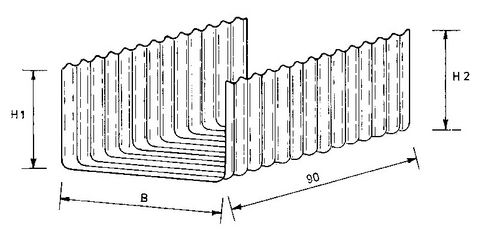

Corrugated profile foundation lateral casing FS-U-Form

System descriptions FS-U-Form:

The MSL girder casing system is closed to the bottom. It consists of individual shaft-profile elements which are manufactured bent in a U-shape in lengths of approx. 90 cm. When laying, 1-2 shafts are overlapped. Angled models can be created with no problem by cutting on site. The fittings are assembled using squared timber by nailing it onto impact points. A straight foundation is achieved by nailing long pieces of squared timber at the top (Photo 2, 3, 4 and 6).

Top spacers with a support have proven to be beneficial for squared timber (Photos 5, 7, 8). In the pile foundation area (Photo 5a), the required openings of the construction steel lead-through can be created easily with a Flex. The 0.5 mm thick shaft-profiled casing elements are very dimensionally stable while the light weight remains the same.

The elements are combined with a minimal freight volume and shipped on a palette (Photo 1). Before pouring the concrete, the casing should be filled with dirt to better absorb the pressure from the fresh concrete from outside or should be stayed with conventional supports. The elements are manufactured in width and height H1 + H2 according to your specifications.

Photos 7+8 show two-part recess frames made of shaft-profile steel plates. The casing is bent into a U-shape at the factory and has two perforations each. On site the casing is bent and attached to the girder or strap casing (Photo 8, 8a). The system is the most affordable MSL model.