Foundation Tube Systems

Lammpost foundations |

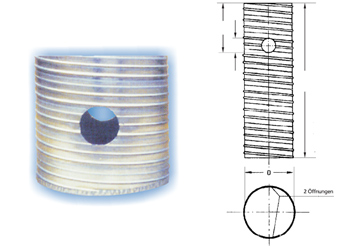

Folded spiral-seam piping of zinc-coated sheet metal type FKVR

Folded spiral-seam piping of zinc-coated sheet metal:

- ready for installation

- with / without inserted base plate / top cover

- with / without cut-outs or drill holes for wiring

System descriptions: MSL foundation piping is manufactured using the same process as for displacement piping - screw-shaped bend, folded leak proof. Reinforcement beading of 2.5 to 9 mmdepending on diameter gives the foundation piping very high strength to resist the pressure of the fresh concrete. The piping can be made in any desired length. It can be supplied with base plate rolled in if the intended use dictates. Loose top covers are offered. Please note these cannot be stepped on in the stan-dard design. Piping is available in diameters from 4 to 200 cm.

When used as lamppost foundations cut-outs or drill holes for later wiring can be provided. MSL foundation piping type FKVR is usually supplied zinc coated. It is used e.g. as externalshuttering for block foundations, as foundation shuttering for posts and signs, as electricity pylon foundations or as shuttering elements for lamp post foundations. In the event of damage it makes it easier and cheaper to replace a lamppost.

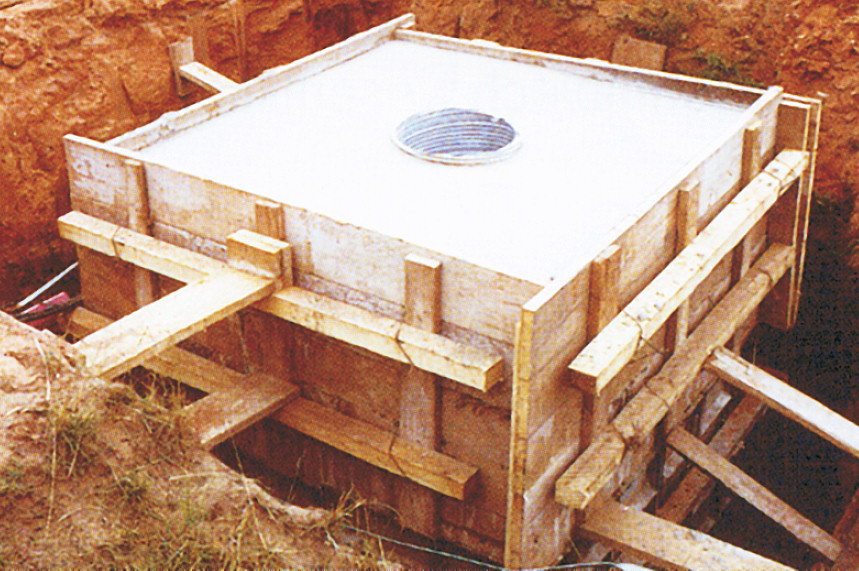

Example of use:

Electricity pylon foundations, photos 5 to 10